GROUNDBREAKING TECHNOLOGY

We are proud to be part of the future. Exeger’s ground-breaking innovation belongs to the third generation of photovoltaic solar cell technology.

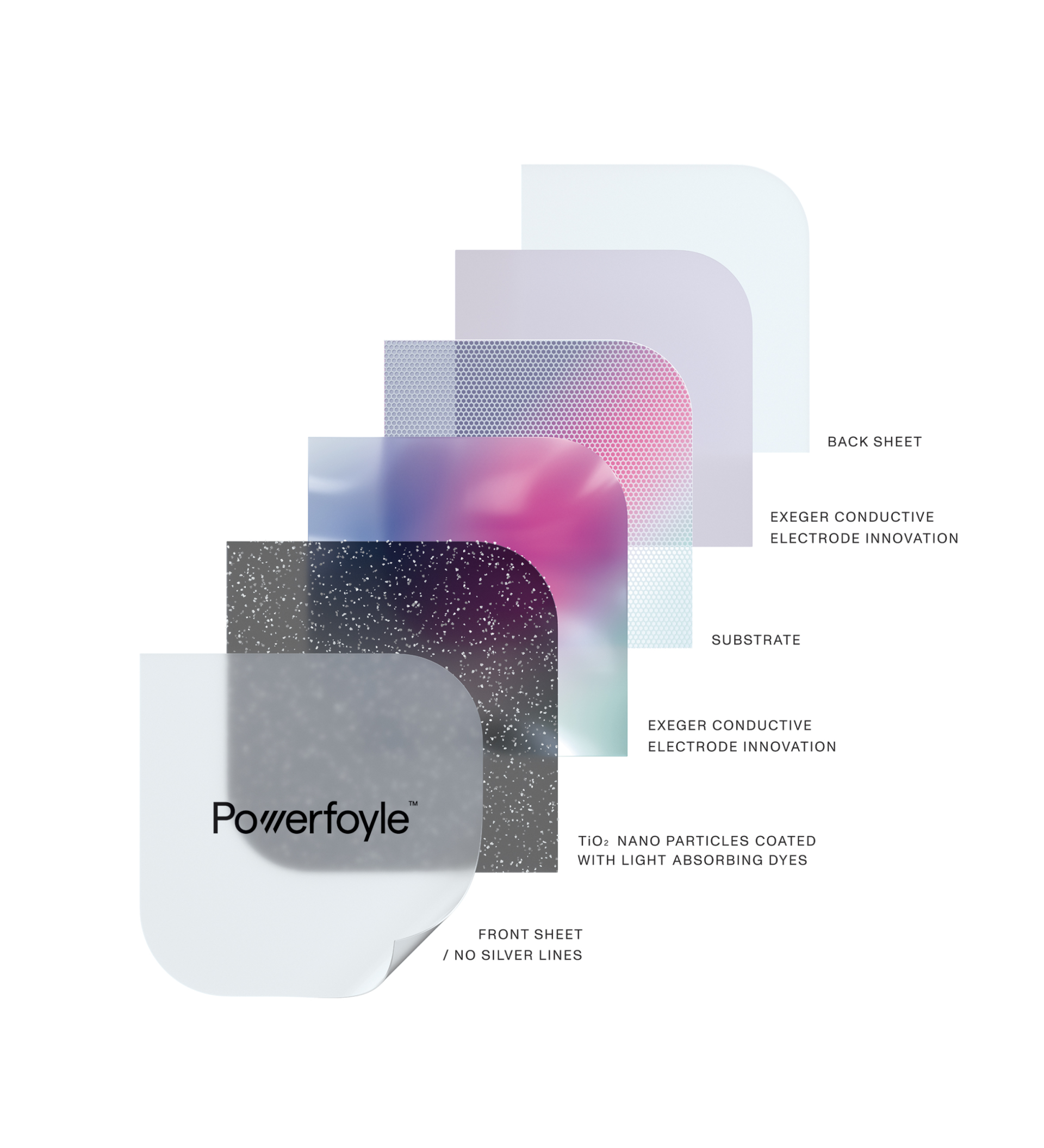

We have reinvented the Dye Sensitized Solar Cell (DSC) with a new architecture that improves real life performance, provides greater flexibility and offers seamless integration possibilities – for all types of products.

Exeger’s solar cell, Powerfoyle, opens a world of new opportunities. Our simple, proven screen printing technology is ideal for large-scale industrial production. Thanks to its exceptional qualities, it is flexible enough to be bent and can be printed in any form. We can seamlessly integrate Powerfoyle into any product, supporting with endless energy.

Powerfoyle has the unique ability to be customized for each product. With light optimization, we adapt the material to power and fit any user needs and behaviors.

A unique conductive electrode material has replaced the traditional expensive and inefficient ITO layer. This is the core of our DSC monolith that sets our material apart from other solar cells. By removing the need for silver lines, we have achieved superior design qualities and in addition, we offer nearly 100% active area – creating endless opportunities and business advantages for our partners and their products.