Sustainable Innovation for a Better Future

Sustainability is gaining importance at all levels of business as companies align their corporate initiatives and activities with the values of their leaders and consumers. This holds true all the way to the end users and decision makers in equipment purchasing.

A 2023 joint study from the International Safety Equipment Association, the American Society of Safety Professionals and EHS Today found that 80% of end-user safety managers consider sustainability an important factor when selecting between brands of PPE and safety equipment. They also expect sustainability to grow in importance as a purchase criteria over the next three years.

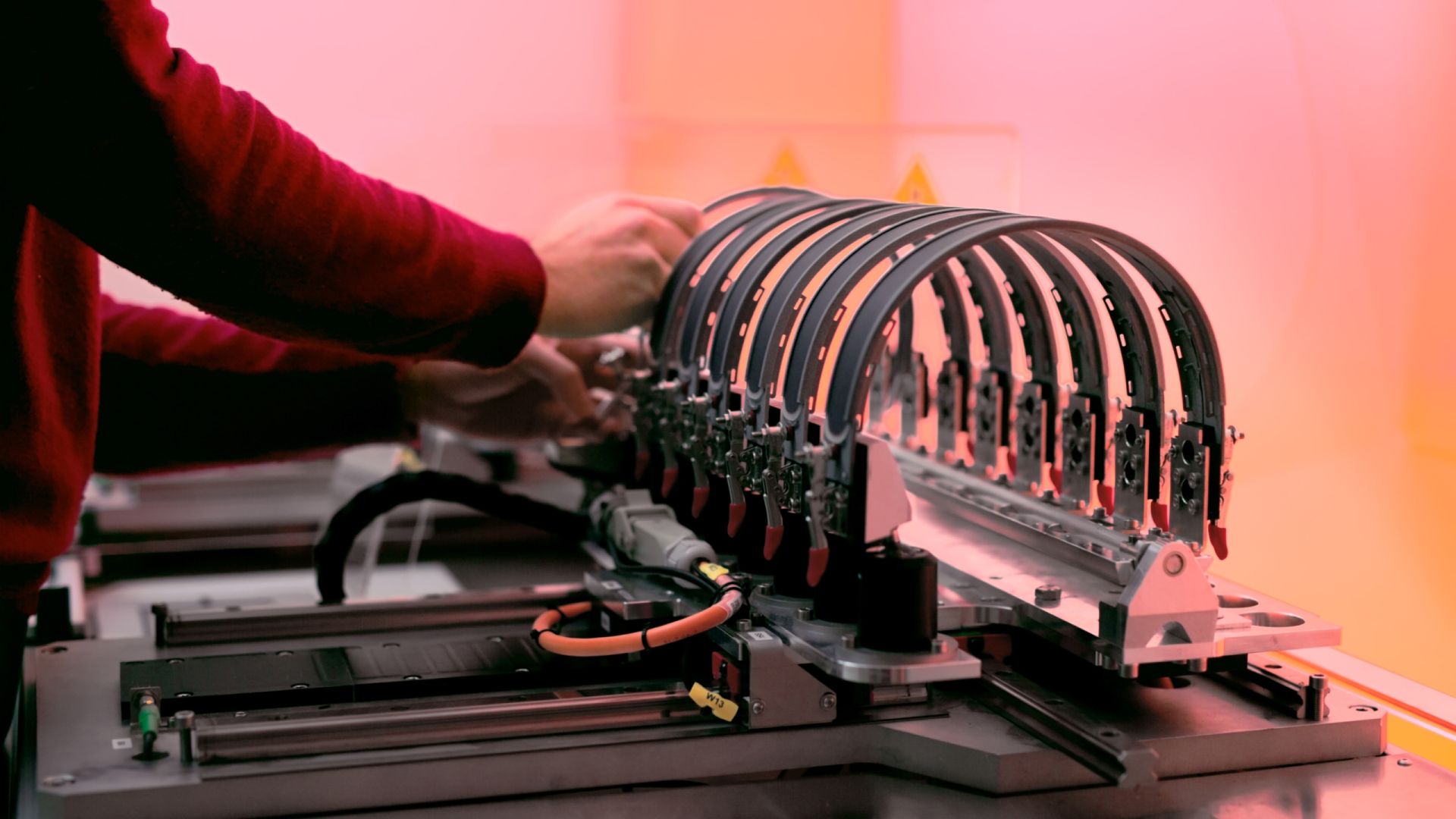

Exeger’s commitment to sustainability is evident in everything that we do. Unlike many other solar cells, Powerfoyle is non-toxic and made using abundantly available raw materials. Our production sites in Stockholm, Sweden, use 100% renewable energy and generate no toxic emissions.

With solar-powered hearing protectors, renewable energy replaces the high environmental cost of battery waste and demonstrates your contribution to a sustainable future.